Recycled Chipboard Partitions Save Money

Although it is ideal to have your products in one box to make it appear professionally handled, a lot of problems can occur during its shipment. Bottled drinks, products stored in breakable containers, and even electronic devices can easily bump into each other and reach its destination worthless.

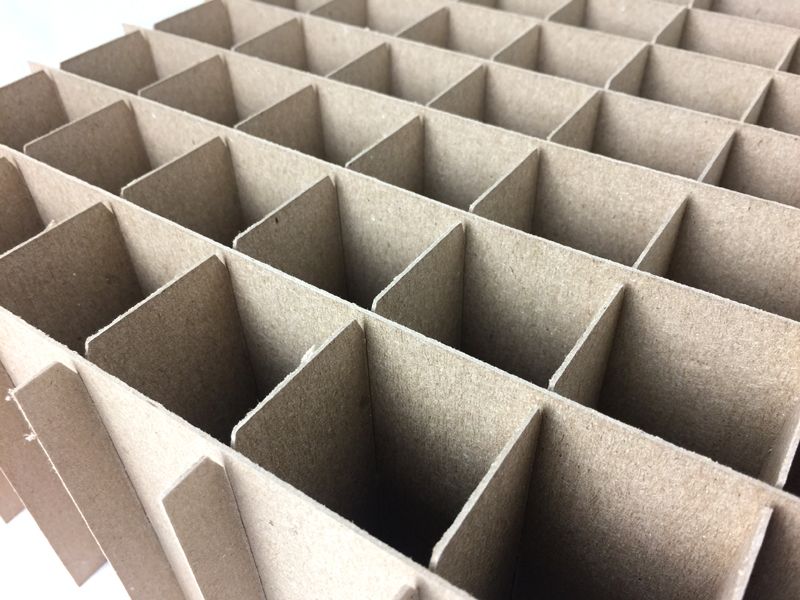

This is where chipboard partitions come in handy. They can be used to secure every material within the box so they arrive in one piece. Not only are they good at protecting your product, but they are also versatile enough to save you tons of money.

Chipboard Partitions Can Be Recycled Many Times or for Other Uses

One of the few good things when using cardboard dividers in Victoria, BC is they can be recycled for other uses. Not only are you protecting the environment, but you also get the return of investment because they can also be repurposed for various other reasons.

Chipboard partitions can the used as storage for many different things including kids toys, paper works, arts and crafts materials, and can be used as a suitcase divider for several things when traveling.

Chipboard packaging can also be reused many times without incurring any issues with your packaging needs. Instead of dumping them into landfills to decompose, most companies use recycled cardboard dividers in Victoria, BC. Having them reprocessed in a recycling plant gives a new life, serving the same purpose.

They are Manufactured Easily to Save You on Energy Consumption

Using a high percentage of recycled materials, chipboard partitions not only limits the cutting of trees but also ensures you get the same service from reused cardboard and paper pulp. They can be remanufactured without affecting their quality and can serve the same purpose as their initial construction.

Using renewable materials, chipboard packaging also lessens the need for newer materials from trees like birch tree or pine tree pulp. Recycling old chipboards and turning them into a new one save a tree from being cut down.

They are easier to make considering that the base material is already in its fundamental form. This lessens the need to break the materials apart and fuse them again to create a new item. Chipboard partitions are reconstructed by using the same materials over and over again.

Recycled chipboard packaging not only saves on precious materials but also on energy consumption because it undergoes only a few processes. Unlike new pulp that needs to be refined and go through tedious procedures of manufacturing which needs more energy.