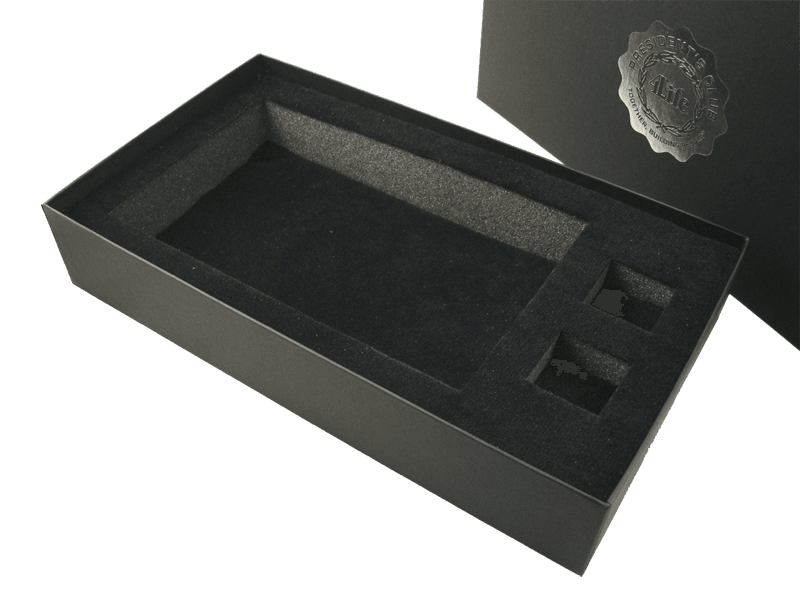

Custom Foam Insert – For Protecting Your Equipment

There are many case manufacturers who send out a large volume of box inserts offering various styles of shipping cases in different dimensions and sizes. Many of these case businesses offer a custom foam insert. A few are layered foam which is cubed and some include solid layered foam. Many would like you to think that their cube foam is a simple method of creating your custom foam insert.

If you ever have utilized cubed foam or attempted to cut and put together your own custom foam insert you’ll have to agree the only actual method of making sure your equipment is protected includes having a professional cut and design your customized foam insert especially for the product you want protected and here is why.

Many cube foam inserts will be cut from 3” or 4” thick foam pieces. Within a typical 15-inch case base there’d be 3-inch to 4-inch thick pieces and 1-inch to 3-inch cubed foam layer. As you develop your cavities within the first 4-inch layer which works great so long as your product is 4-inches thick or less. What will happen if one of your products is, say, 6-inches thick.

One other issue with cube foam is that as the products are pulled out of their cavities then repeatedly pushed back inside their cavities, the cube foam usually degrades. Frequent pushing and pulling of the cubed foam cavities will cause them to begin degenerating in to smaller pieces and parts of the foam usually break off. Now the case will become filled with pick and pluck pieces of foam instead of the custom cavities you were thinking you would get when you bought the case.

By having a customized foam insert cut you do not need to be concerned with flaking because the cavity was made by cutting one solid foam piece. Plus, because custom foam inserts start as massive foam blocks you do not need to be concerned with how thick layers are because not just is the horizontal dimension accurate yet the vertical dimension may be cut to any required height.

In every way a customized foam insert is worth the small extra money from the start. Though pick and pluck foam is cheaper at the start, by the time you replace the foam a few times before realizing you should’ve had customized foam made to start with, customized foam winds up being less expensive if invested in from the start.